|

|

How It Works.... |

Soda blasting is a process used in cleaning and de-painting. Similar to the familiar method, sandblasting, but without the concerns associated with sandblasting. Prior to soda blasting, all kinds of cleaning and de-painting projects were inappropriately performed by sand blasting, without a viable alternative. Soda blasting is "soft media" blasting, using blasting "medias" ( ie materials ) that are relatively soft, providing an enviromentally sensible, low impact alternative to sandblasting. Soda blasting is a process used in cleaning and de-painting. Similar to the familiar method, sandblasting, but without the concerns associated with sandblasting. Prior to soda blasting, all kinds of cleaning and de-painting projects were inappropriately performed by sand blasting, without a viable alternative. Soda blasting is "soft media" blasting, using blasting "medias" ( ie materials ) that are relatively soft, providing an enviromentally sensible, low impact alternative to sandblasting.

As the Moh's Hardness scale to the left indicates sodium bicarbonate has a relative hardness of 2.5, calcium carbonate is at 3.0, while sand has a relative hardness of 7.0, much too aggressive for many applications. As the Moh's Hardness scale to the left indicates sodium bicarbonate has a relative hardness of 2.5, calcium carbonate is at 3.0, while sand has a relative hardness of 7.0, much too aggressive for many applications.

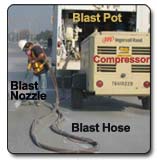

A simplified explanation of how it works. The compressor sends compressed air to the blast pot, where the blast media is mixed into the blast stream and then sent down the blast hose to the nozzle. The air pressure, amount of media, and orifice size of the nozzle are all variables that can be controlled to meet the requirements of the specific application. A simplified explanation of how it works. The compressor sends compressed air to the blast pot, where the blast media is mixed into the blast stream and then sent down the blast hose to the nozzle. The air pressure, amount of media, and orifice size of the nozzle are all variables that can be controlled to meet the requirements of the specific application.

|

|